Use Case

How a Leading Confectionery Manufacturer Increased Stock Volume by 40% with Real-Time Insights

Background

A global leader in the confectionery industry wanted to maximize sales during their monthly half-price promotions at key retailers. These promotions placed discounted chocolates in multiple store locations - such as aisles and gondola ends - to drive impulse purchases. To achieve optimal ROI, the brand required each location to maintain a Minimum Display Quantity (MDQ), the minimum amount of product needed on display to ensure visibility and effectiveness of the promotion. However, ensuring sufficient stock to meet the MDQ during these promotions proved to be a challenge.

Challenges

Despite the popularity of their promotions, the manufacturer observed sales were falling short of expectations, creating a significant gap between their goals and results. While the brand’s half-price deals attracted attention, they suspected that inadequate stock levels were preventing customers from making purchases, particularly during high-traffic weekend periods when demand peaks. This issue was exacerbated by the unavailability of field teams over the weekend, leaving the brand unable to address stockouts in real time.

The challenges were multifaceted, including both operational inefficiencies and visibility gaps:

- Poor availability in high-traffic areas:

These prime locations, such as gondola ends, are critical for driving impulse purchases, but frequent stockouts left shelves unappealing and undermined the campaign’s ROI. - Inconsistent stock monitoring across stores:

Without reliable, real-time data, the manufacturer struggled to understand how well individual locations were executing the promotion, leading to missed opportunities to correct stock issues. - Limited insights into stock levels:

Weekends are critical sales periods for retail promotions, but the lack of actionable data during these times left the brand unable to react to stock shortages when they mattered most.

Solution

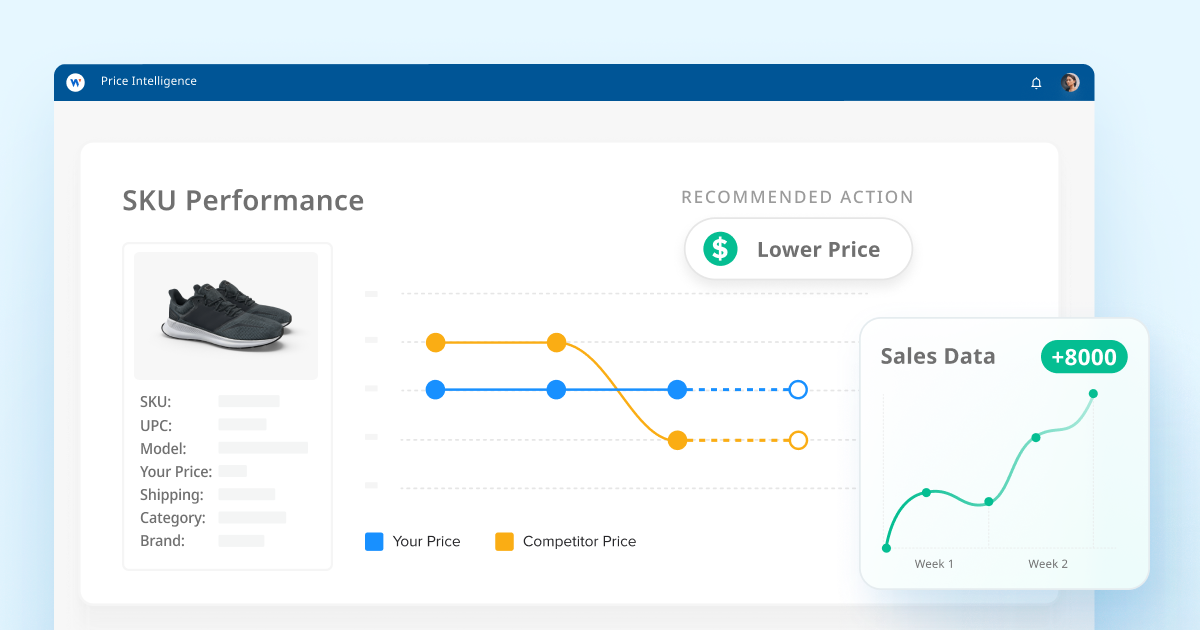

The manufacturer partnered with Wiser, leveraging its extensive mystery shopping network to gain real-time insights and improve in-store availability. Key actions included:

- Collecting real-time stock level data:

Mystery shoppers gathered detailed data at both SKU and store level, focusing on product placement in high-impact areas such as aisles and gondola ends. This granular visibility allowed the manufacturer to pinpoint where stock levels were insufficient to meet consumer demand. - Tracking stock availability trends:

Data was collected daily, capturing fluctuations in stock levels from weekdays to weekends. This analysis provided a clear understanding of when and where availability issues were most pronounced, particularly during peak shopping periods. - Identifying stores falling below MDQ thresholds:

By monitoring stock levels in high-visibility locations, Wiser helped the brand identify stores that failed to meet the Minimum Display Quantity (MDQ) needed to optimize promotional ROI. This enabled the manufacturer to focus resources on the locations most in need of intervention.

Results

Wiser delivered measurable, impactful results that transformed the performance of the brand’s promotional campaigns, equipping them with the tools to improve in-store availability and maximize sales outcomes. Key results included:

- Secured a 40% increase in stock volume:

Leveraging Wiser data, the manufacturer successfully negotiated a significant 40% stock volume increase for the next promotional period, addressing previous availability challenges. - Proactive issue resolution:

The partnership enabled the brand to identify and address stock shortages during critical sales periods, ensuring shelves remained stocked and maximizing the return on investment for future campaigns. - Identified critical stock shortages:

Data collected by crowdsourced mystery shoppers revealed that by Saturday of the promotion week:- 45% of stores had stock levels below the Minimum Display Quantity (MDQ) in aisles.

- Over 60% of stores failed to meet MDQ requirements at gondola ends, impacting visibility and sales potential.

These insights offered the manufacturer a clear roadmap for addressing stock availability issues during future promotions, allowing them to fine-tune their strategy and improve in-store execution. With Wiser’s retail intelligence, the confectionery manufacturer significantly enhanced in-store availability, prevented missed sales opportunities, and drove higher revenue during their promotional campaigns. This ongoing partnership demonstrates the power of leveraging data to make smarter, more informed decisions and deliver better outcomes in a competitive retail landscape.

Want help launching your own Perfect Store initiative? Get in touch with us.